Principle of operation

This machine is a through-flow continuous drying equipment, which is used for drying flaky, strip and granular materials with good air permeability, especially suitable for dehydrated vegetables, Chinese herbal pieces and other materials with high water content but high temperature is not allowed. This series of dryers has the advantages of fast drying speed, high evaporation intensity and good product quality. The dehydrated cake-like paste materials can also be dried after granulation or rod-like.

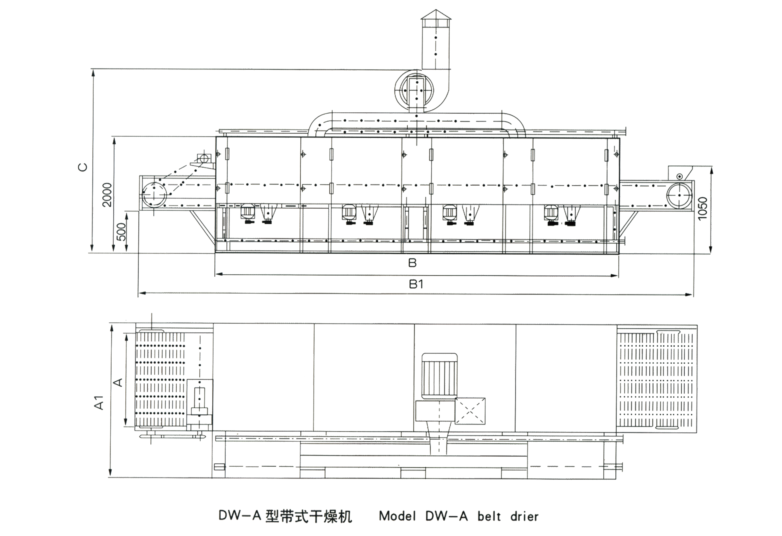

The material is evenly spread on the mesh belt by the feeder. Generally, the mesh belt adopts 12-60 mesh stainless steel wire mesh, which is dragged by the transmission device to move in the dryer. The dryer consists of several units, and the hot air of each unit circulates independently. Part of the tail gas is discharged by a special dehumidifying fan, and the waste gas is controlled by a regulating valve. The hot air passes through the mesh belt covered with materials from bottom to top or from top to bottom to complete the process of heat and mass transfer and take away the moisture of the materials. The mesh belt moves slowly, and the running speed can be adjusted freely according to the material temperature, and the dried finished product continuously falls into the receiver. The upper and lower circulation units can be flexibly equipped according to the needs of users, and the number of units can also be selected according to needs.

Process flow diagram

Performance characteristics

◎ Air volume, heating temperature, material residence time and feeding speed can be adjusted to achieve ideal drying effect.

◎ The equipment configuration is flexible, and mesh belt washing system and material cooling system can be used.

◎ Most of the air is recycled, which saves energy.

◎ Unique air distribution device makes the hot air distribution more uniform and ensures the consistency of product quality.

◎ The heat source can be steam, heat transfer oil, electricity or coal-fired (oil-fired) hot blast stove.

Applied range

Dehydrated vegetables, melon seeds, dates, peanuts, pellet feed, monosodium glutamate, coconut milk, organic pigments, synthetic rubber, polypropylene fiber, medicines, medicinal materials, small wooden products, plastic products, aging and curing of electronic devices, etc.

Technical specifications

Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

Number of units | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

Bandwidth(m) | 1.2 | 1.6 | 2 | |||||

Dry section length(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

Paving thickness(mm) | ||||||||

Usage temperature(℃) | 50-140 | |||||||

Vapor pressure(Mpa) | 0.2-0.8 | |||||||

Steam consumption (kg/h) | 120-300 | 150-375 | 150-400 | 180-500 | 180-500 | 225-600 | 450-1200 | |

Drying time (h) | 0.2-1.2 | 1.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.5-3 | |

Drying strength kg water/h | 60-160 | 80-200 | 85-220 | 100-260 | 100-260 | 120-300 | 240-600 | |

Total power of equipment (kw) | 11.4 | 13.6 | 14.6 | 18.7 | 19.7 | 24.5 | 51 | |

| Outline dimension | Long(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Wide(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 | |

| Tall(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Gross(kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |