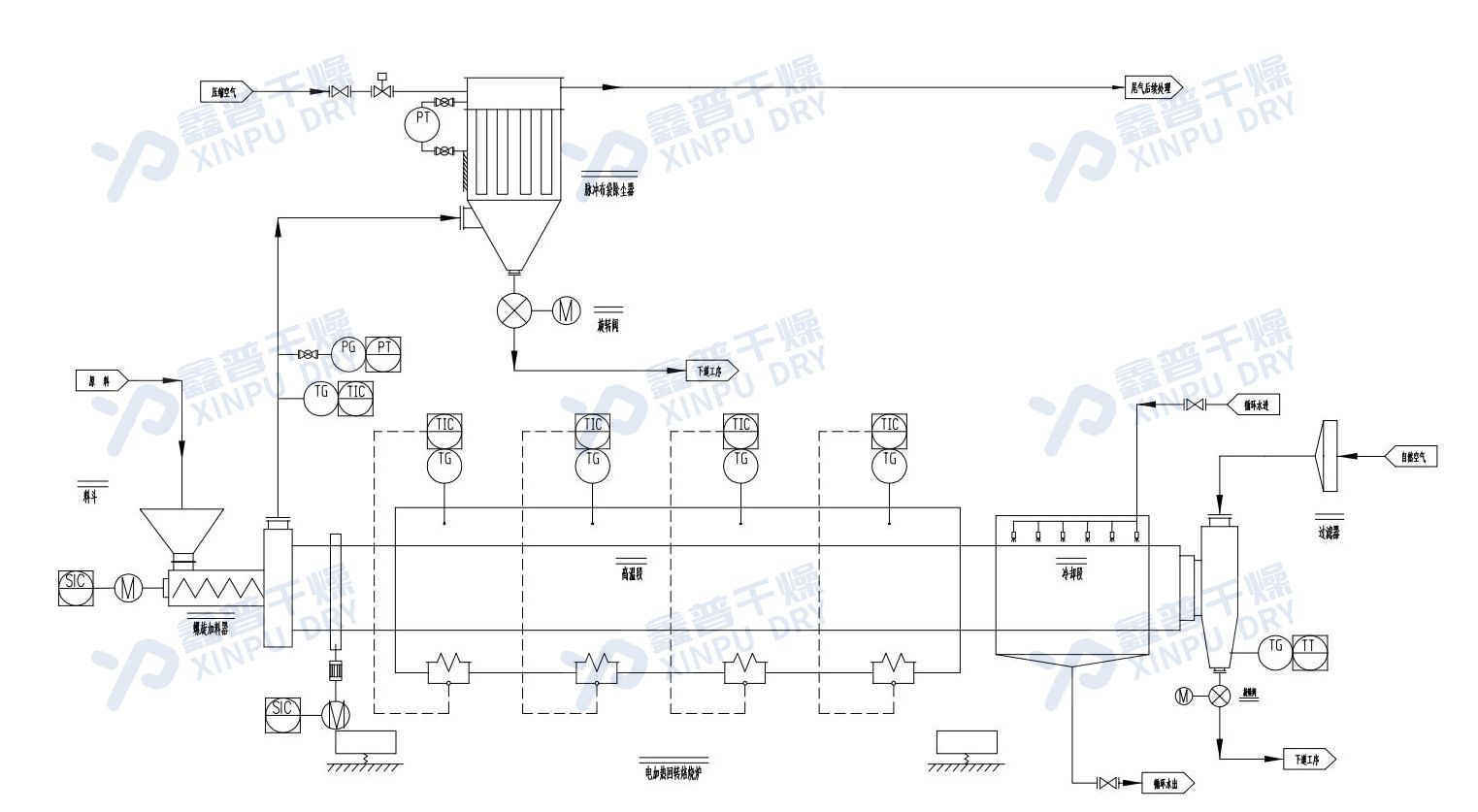

Process flow diagram

FEATURES

Traditional drying of lithium carbonate adopts vertical disc drying. Compared with vertical disc drying equipment, rotary kiln drying has stronger stability and lower failure rate, and both electric heating and natural gas heating are applicable.

Electric heating roaster

Good sealing effect and high degree of automation.

◎ Automatic control of roasting temperature and sectional setting.

◎ The heating system is safe and reliable.

◎ The surface temperature rise of the insulation furnace is lower than the ambient temperature +25℃, and the heat loss is small.

◎ The equipment has simple and compact structure, small volume and light weight.

◎ Efficient, energy-saving and pollution-free.

◎ Low operating intensity, simple maintenance and good operating environment.

◎ Compared with other energy roasting furnaces, the auxiliary equipment is simple and easy to maintain.

◎ Operating temperature reaches ~550℃

Gas-fired roaster

◎ Good sealing effect, reducing material loss and heat loss.

◎ Full combustion of gas and high thermal efficiency.

◎ Automatic control of roasting temperature and subsection control.

◎ With unexpected power failure protection system.

◎ Good thermal insulation performance, reducing heat loss.

◎ The combustion control system is safe and reliable

◎ The equipment is simple and compact in structure, small in size and light in weight, and the furnace body can be directly assembled on site.

◎ Compared with other energy roasting furnaces, the auxiliary equipment is simple and easy to maintain.

◎ Operating temperature reaches ~550℃