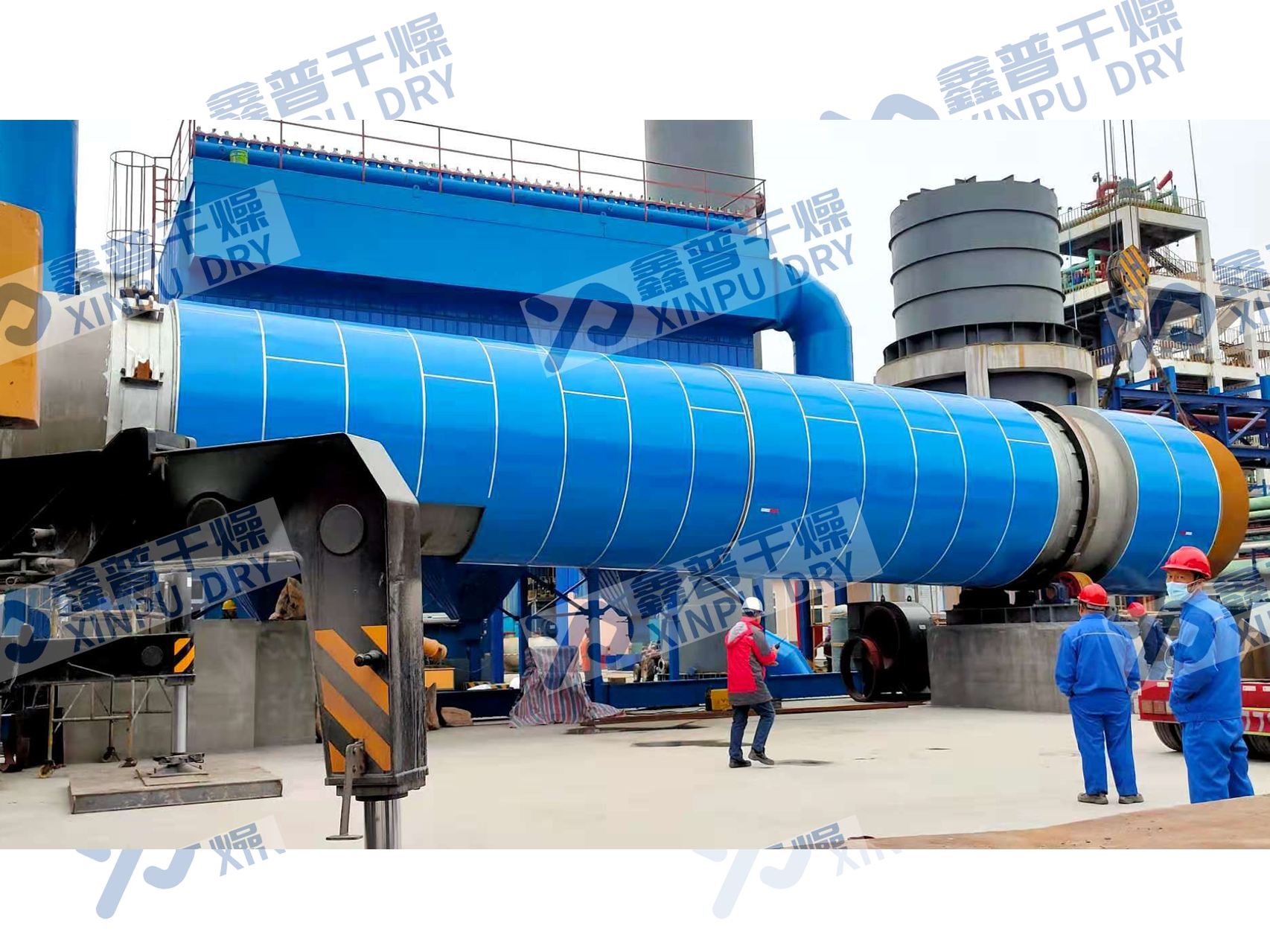

Principle of operation

Low temperature removal is used for electrolyte removal in battery recovery. After the crushed battery is put into the dryer from one end, the materials are evenly distributed and dispersed in the dryer under the turning of the plate-copying machine evenly distributed in the inner cylinder, and fully contact with the hot air in parallel flow (countercurrent), which accelerates the drying heat transfer and transmits it to the driving force. In the drying process, under the action of the inclined plate and hot air flow, the material can be controllably moved to the star-shaped discharge valve at the other section of the dryer to discharge the finished product.

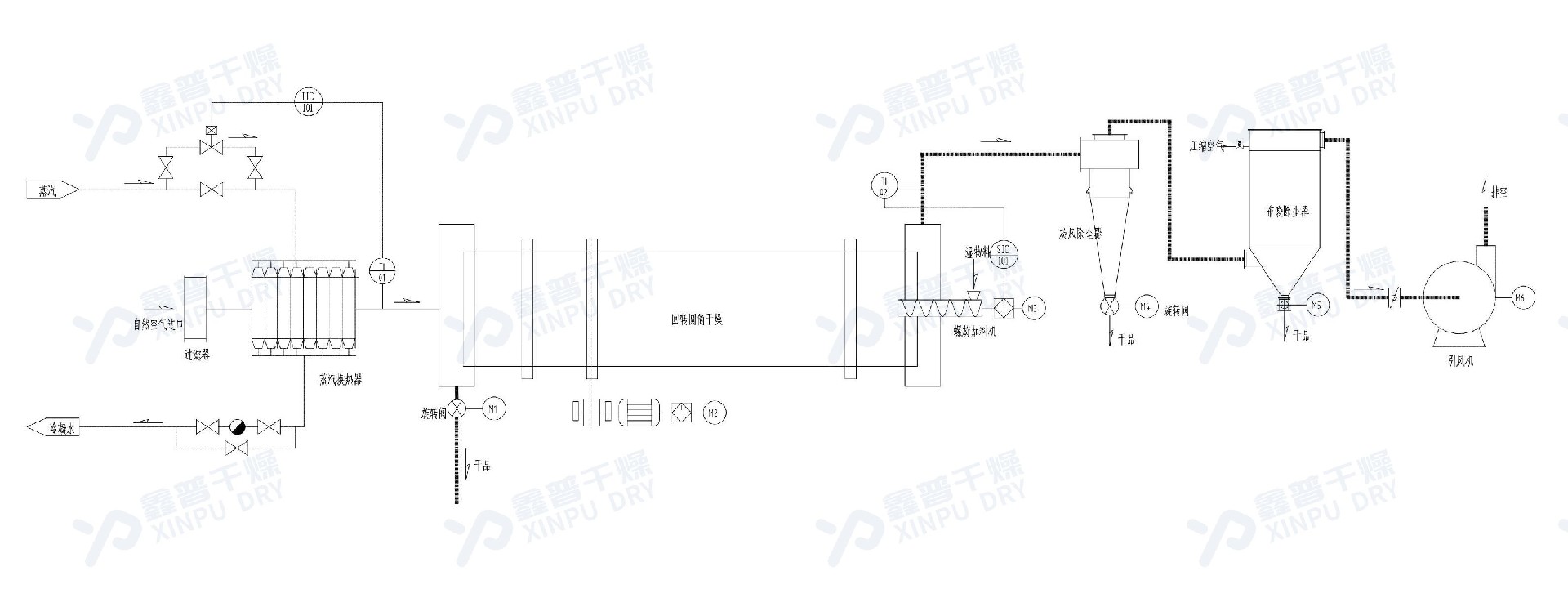

Process flow diagram

Performance characteristics

◎ Rotary dryer has a high degree of mechanization and a large production capacity.

◎ The resistance of fluid passing through the cylinder is small, and the function consumption is low.

◎ Strong adaptability to material characteristics.

◎ Stable operation, low operating cost and good product drying uniformity.