Cases that have been built and put into use

45,000 tons/year anhydrous iron phosphate production line

30,000 tons/year anhydrous iron phosphate production line

25,000 tons/year anhydrous iron phosphate production line

20,000 tons/year anhydrous iron phosphate production line

15,000 tons/year anhydrous iron phosphate production line

10,000 tons/year anhydrous iron phosphate production line

5,000 tons/year anhydrous iron phosphate production line

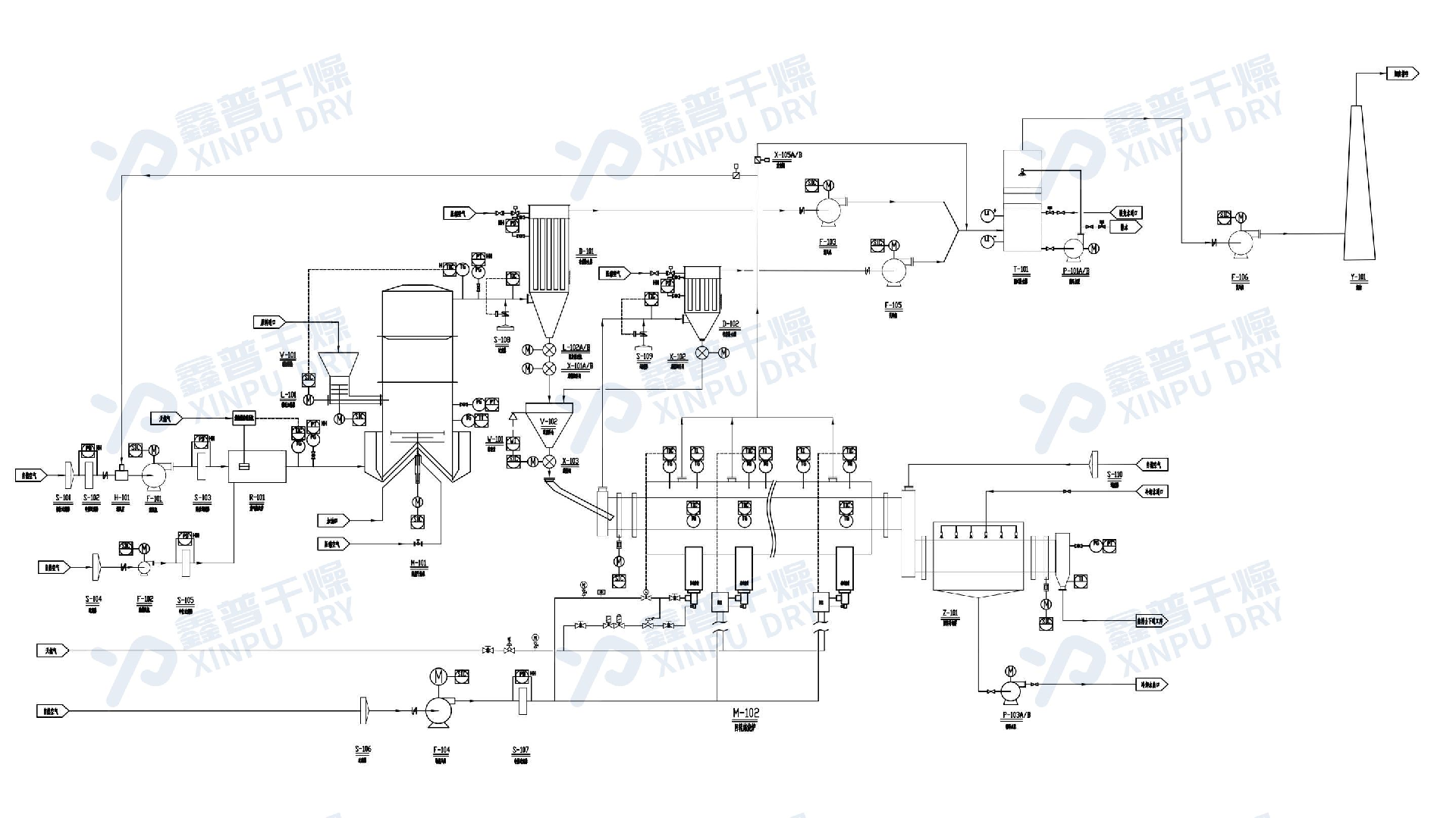

Process flow diagram

DESCRIPTIONS

◎ The main components of the system are rotary flash drying system and rotary roaster system.

◎The rotary flash drying system is mainly composed of heater, feeder, dryer, dust collector, fan and control system. Due to the special properties of some special materials, the feeders in the system are specially designed and can be selected according to the material characteristics. The heater is a new structure with higher thermal efficiency and safety. The dust collector is designed according to the material characteristics.

◎ Rotary roaster is mainly composed of high-temperature calcination system, cooling system, heating system (electric heating or natural gas heating), dust removal system and control system. A weighing device can be selected for the transition bin, and the rotary dynamic continuous calcination can ensure the product quality and reduce the introduction of foreign matter/foreign phase.

FEATURES

◎ The automatic control system can react and adjust quickly according to the user's requirements or the change of external conditions. It is mainly manifested in automatic control of inlet air temperature, continuous control of outlet air temperature and feed rate (to ensure consistent product quality) and system pressure adjustment (automatic or manual) to ensure system stability. The control precision of the roaster is high, and it is controlled by zones. The heating temperature in each zone is controlled by the heating source. The material temperature in each zone can be displayed on the control cabinet through special temperature measurement, which is convenient for users to adjust and control when the process changes.

◎ The system can well control the introduction of metallic magnetic foreign bodies, and can control the introduction of metallic magnetic foreign bodies at a very low level.

◎ Simplify and optimize the system flow and improve the logistics quality.

◎ The whole baking furnace barrel is processed to ensure the accuracy of the barrel.

◎When roasting, inert gas and other carrier gas can be introduced according to the material requirements.

◎ The system can be equipped with a waste heat recycling device, which can save energy by 20~30%.