Principle of operation

Pulsed air-flow dryer is a high-yield and rapid drying equipment. It adopts the principle of instantaneous drying, drives wet materials to suspend in hot air by using the rapid movement of heat-carrying air, thus strengthening the whole drying process and improving the rate of heat and mass transfer. After air-flow drying, almost all unbound moisture can be removed (for example, the water content of starch and other materials is less than or equal to 40%, and the finished product can be discharged at 13.5%), and the dried materials can be dried.

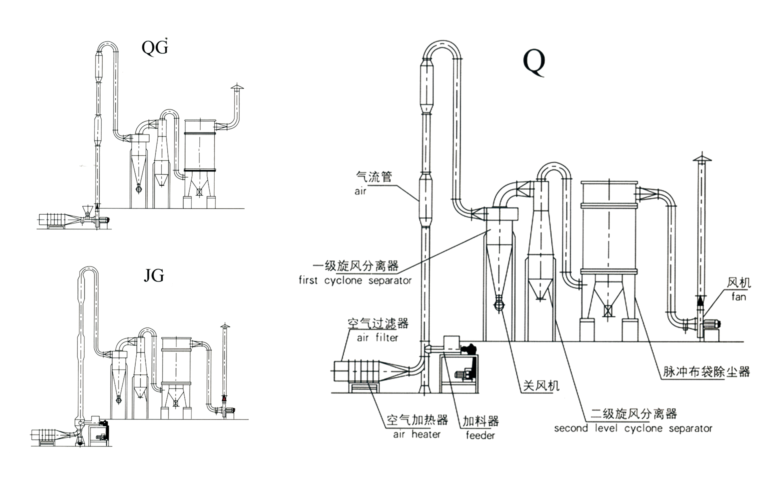

Process flow diagram

Product features

Airflow drying has the advantages of high automation, low investment, low energy consumption, less manpower and factory area, and wide versatility. It is a better modern equipment.

Applied range

Airflow dryer is suitable for drying and dehumidifying powdery materials in pharmaceutical, chemical, food, building materials, plastics and other industries, such as starch, fish meal, salt, distiller's grains, feed, gluten, plastic resin, mineral powder, coal powder, sugar chloric acid, A.S.C. formic acid, 2.3 acid, polypropylene chloroacetate, sodium sulfate, sodium metabisulfite and so on.

Technical specifications

Specifications/Parameters | QG-50 | QG-100 | QG-250 | QG-500 | QG-1500 | |

Moisture evaporation | kg/h | 50 | 100 | 250 | 500 | 1500 |

Installed power | kw | 7 | 13 | 25 | 43 | 150 |

Floor area | ㎡ | 20 | 32 | 64 | 96 | 200 |

| Height | m | 14 | 14 | 15 | 18 | 20 |