Principle of operation

Hot air enters the bottom of the drying equipment tangentially, and forms a powerful rotating wind field driven by the agitator. Paste materials enter the dryer from the screw feeder. Under the strong action of high-speed rotating paddles, the materials are dispersed under the action of impact, friction and shear force, and the block materials are quickly crushed, fully contacted with hot air, heated and dried. After dehydration, the dry material rises with the hot air flow, and the grading ring intercepts the large particles, while the small particles are discharged from the center of the ring outside the dryer and recovered by the cyclone separator and dust collector. The undried or large materials are thrown to the wall by centrifugal force and fall to the bottom again to be crushed and dried.

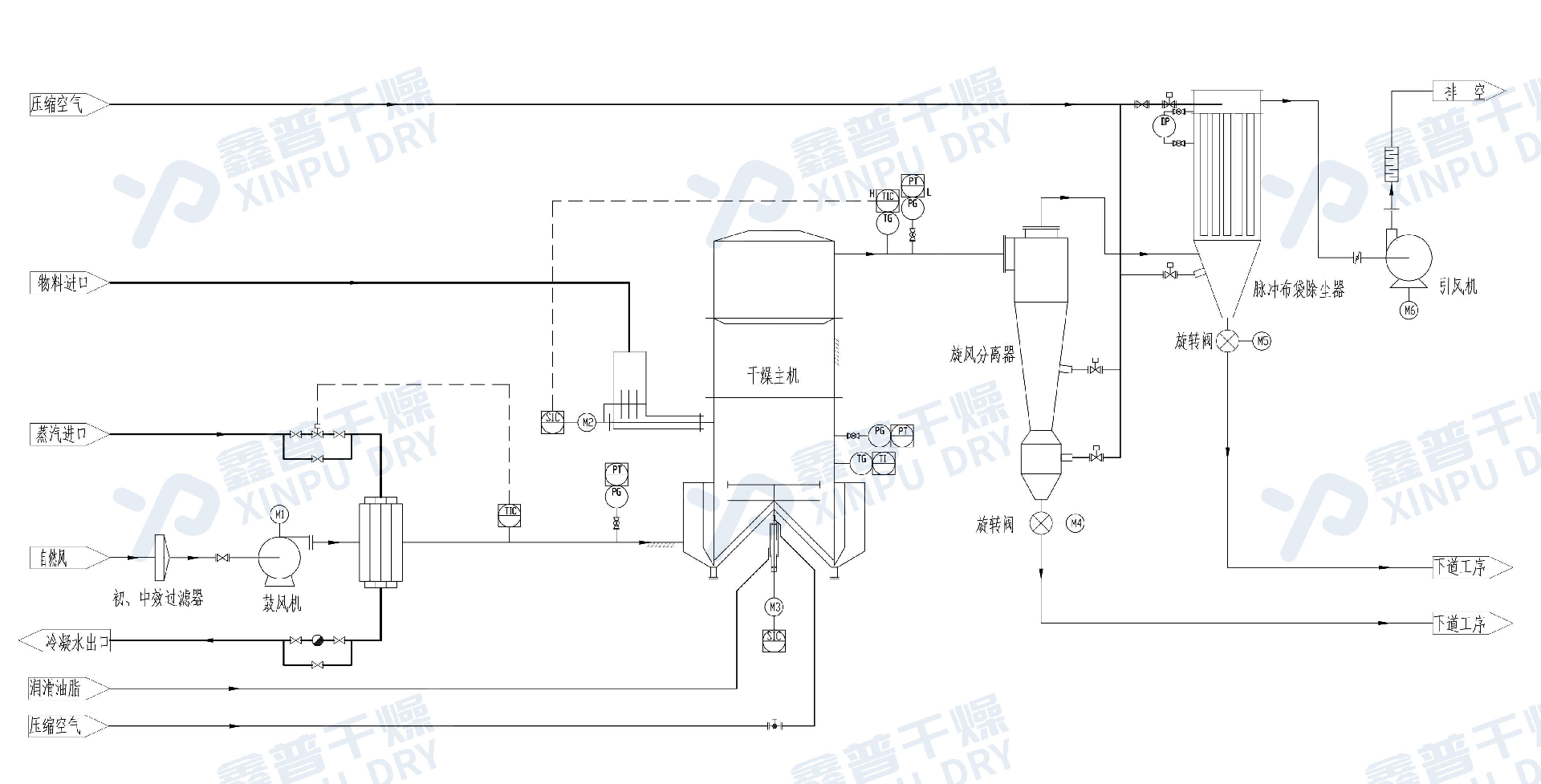

Process flow diagram

Performance characteristics

◎ Organic combination of cyclone, fluidization, spouting and crushing and grading technologies.

◎ Compact equipment, small volume, high production efficiency and continuous production.

◎ High drying intensity, low energy consumption and high thermal efficiency.

◎ Short retention time of materials and good quality of finished products, which can be used for drying heat-sensitive materials.

◎ Negative pressure or micro-negative pressure operation, good airtightness, high efficiency and elimination of environmental pollution.

Applied range

It is widely used for drying filter cake-like, block-like or powdery materials, such as materials after mechanical dehydration after filter press and centrifuge.

Technical specifications

Model specification | Diameter (MM) | Maximum evaporation (KG/H) | Host power (KW) | Overall size of main engine (MM) | Main engine weight (KG) |

XSG-200 | 200 | 15 | 2.2-3 | 500×500×2600 | 900 |

XSG-400 | 400 | 50 | 4-5.5 | 920×920×3800 | 1800 |

XSG-600 | 600 | 110 | 5.5-7.5 | 1200×1200×4200 | 2100 |

XSG-800 | 800 | 200 | 7.5-11 | 1400×1400×4700 | 2500 |

XSG-1000 | 1000 | 300 | 11-15 | 1600×1600×5200 | 2900 |

XSG-1200 | 1200 | 450 | 15-18.5 | 2100×2100×5500 | 4500 |

XSG-1400 | 1400 | 640 | 18.5-22 | 2400×2400×6500 | 5600 |

XSG-1600 | 1600 | 830 | 22-30 | 2500×2500×6800 | 6500 |

XSG-1800 | 1800 | 1000 | 30-37 | 2600×2600×7000 | 9300 |

XSG-2000 | 2000 | 1300 | 37-55 | 3000×3000×7500 | 11500 |

| XSG-2200 | 2200 | 1800 | 45-75 | 3400×3400×8500 | 16000 |