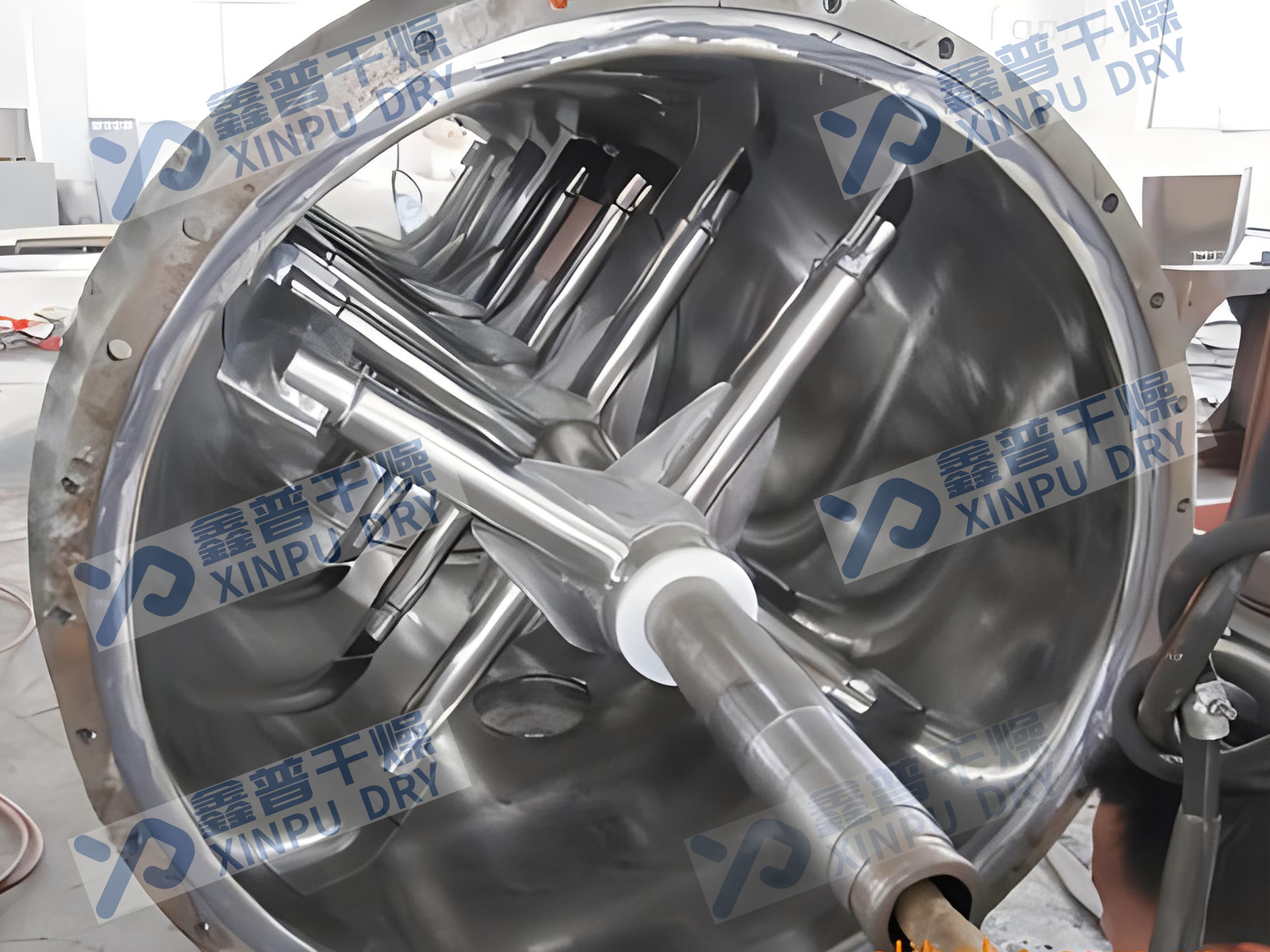

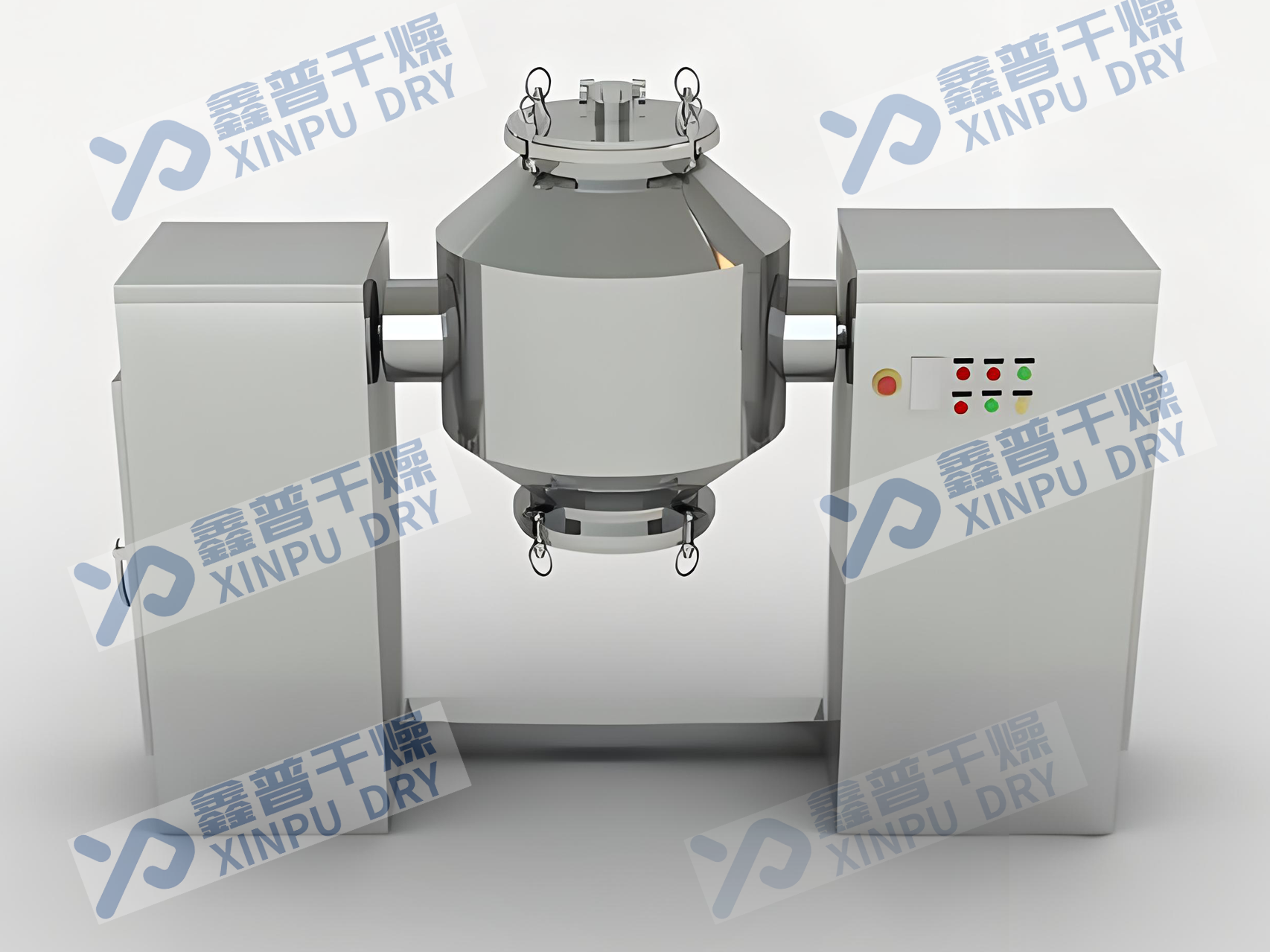

Principle of operation

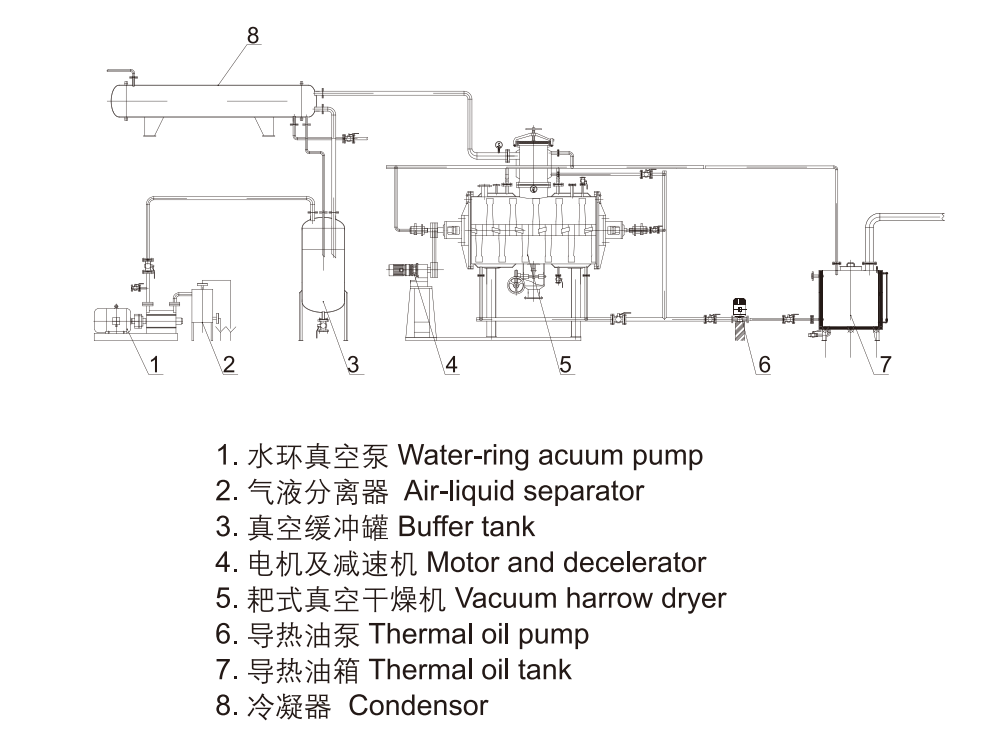

The vacuum rake dryer is a novel horizontal intermittent vacuum drying equipment. The wet material is continuously removed from the hot surface by conduction and heat transfer, and the material is pushed in the container to form a circulating flow. After the water evaporates, it is pumped out by a vacuum pump.

Process flow diagram

Performance characteristics

◎ This machine adopts large-area sandwich heating mode, with large heat transfer surface and high thermal efficiency.

◎ This machine is equipped with stirring, which makes the material form a continuous circulation state in the cylinder, further improving the uniformity of material heating.

◎ This machine is equipped with stirring, so that the paste, paste and paste materials can be dried smoothly.

Applied range

◎ The following materials are dried in the pharmaceutical, food and chemical industries:

◎ Suitable for paste, paste and powder materials;

◎ Heat-sensitive materials requiring low-temperature drying;

◎ Oxidizable, explosive, highly irritating and highly toxic materials;

◎ Materials requiring recovery of organic solvents.

Technical specifications

Project | Type | ||||||||

Name | Unit | ZPG-500 | ZPG-750 | ZPG-1000 | ZPG-1500 | ZPG-2000 | ZPG-3000 | ZPG-4000 | ZPG-5000 |

Effective working volume | L | 300 | 450 | 600 | 900 | 1200 | 1800 | 2400 | 3000 |

Hs | ㎡ | ~6 | ~7.6 | ~9.3 | ~12.3 | ~14.6 | ~19.3 | ~22.0 | ~24.1 |

Mixing speed | rpm | 5-20 stepless speed regulation | 4-12 stepless speed regulation | ||||||

Power | kw | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 22 | 30 |

Interlayer design pressure | MPa | ≤0.3 | |||||||

Heat source form | Steam, heat transfer oil or hot water | ||||||||

Vacuum degree in cylinder | MPa | -0.09~0.096 | |||||||

Project | Type | |||||

Name | Unit | ZPG-6000 | ZPG-8000 | ZPG-10000 | ZPG-12000 | ZPG-15000 |

Effective working volume | L | 3600 | 4800 | 6000 | 7200 | 9000 |

Hs | ㎡ | ~26.6 | ~31.5 | ~36.0 | ~39.5 | ~46.6 |

Mixing speed | rpm | 3-9 stepless speed regulation | 2-6 stepless speed regulation | |||

Power | kw | 45 | 55 | 55 | 75 | 75 |

Interlayer design pressure | MPa | ≤0.3 | ||||

Heat source form | Steam, heat transfer oil or hot water | |||||

Vacuum degree in cylinder | MPa | -0.09~0.096 | ||||

Note: Water evaporation is related to the characteristics of materials, heat source form, heat source temperature and vacuum degree.