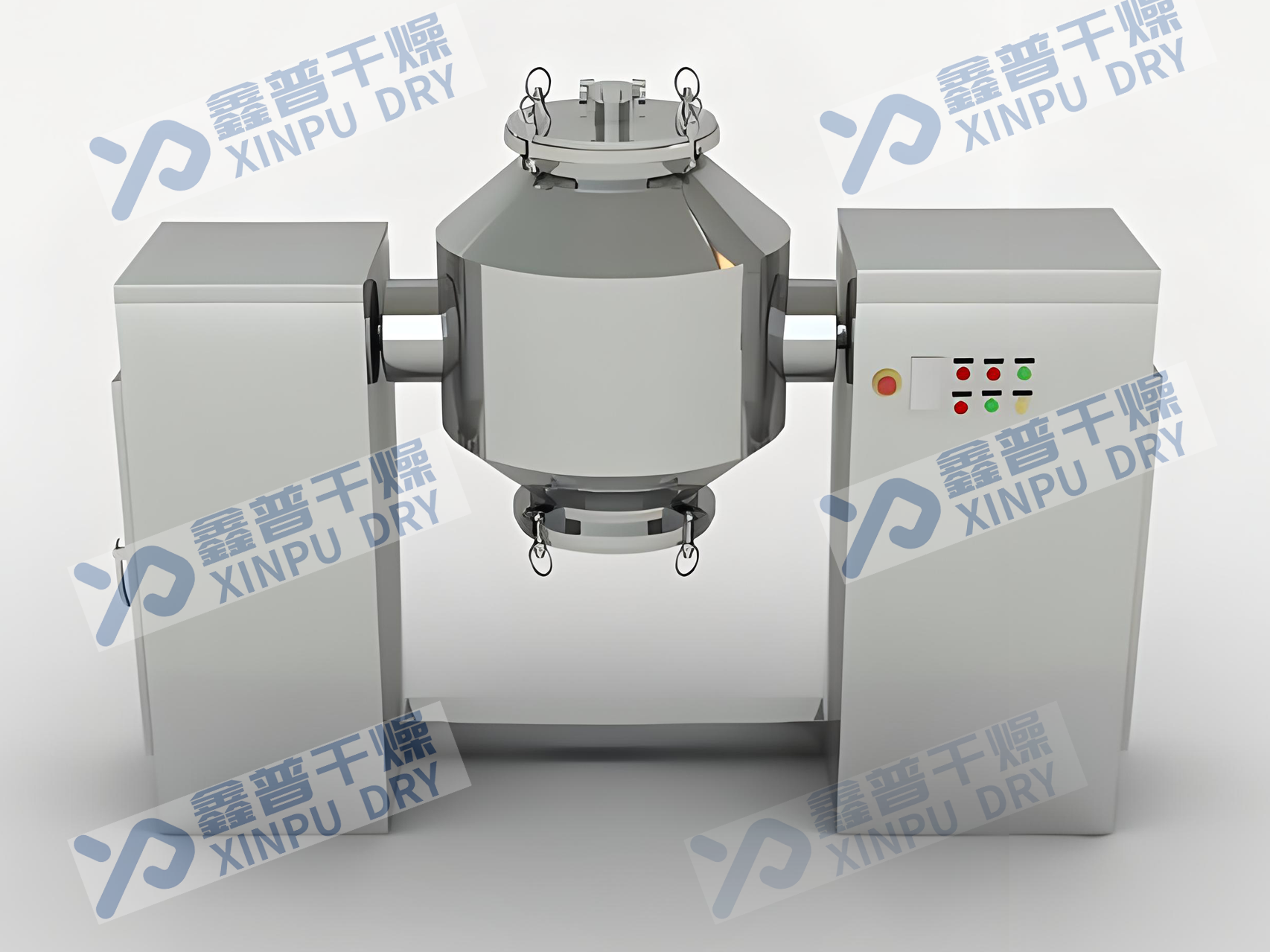

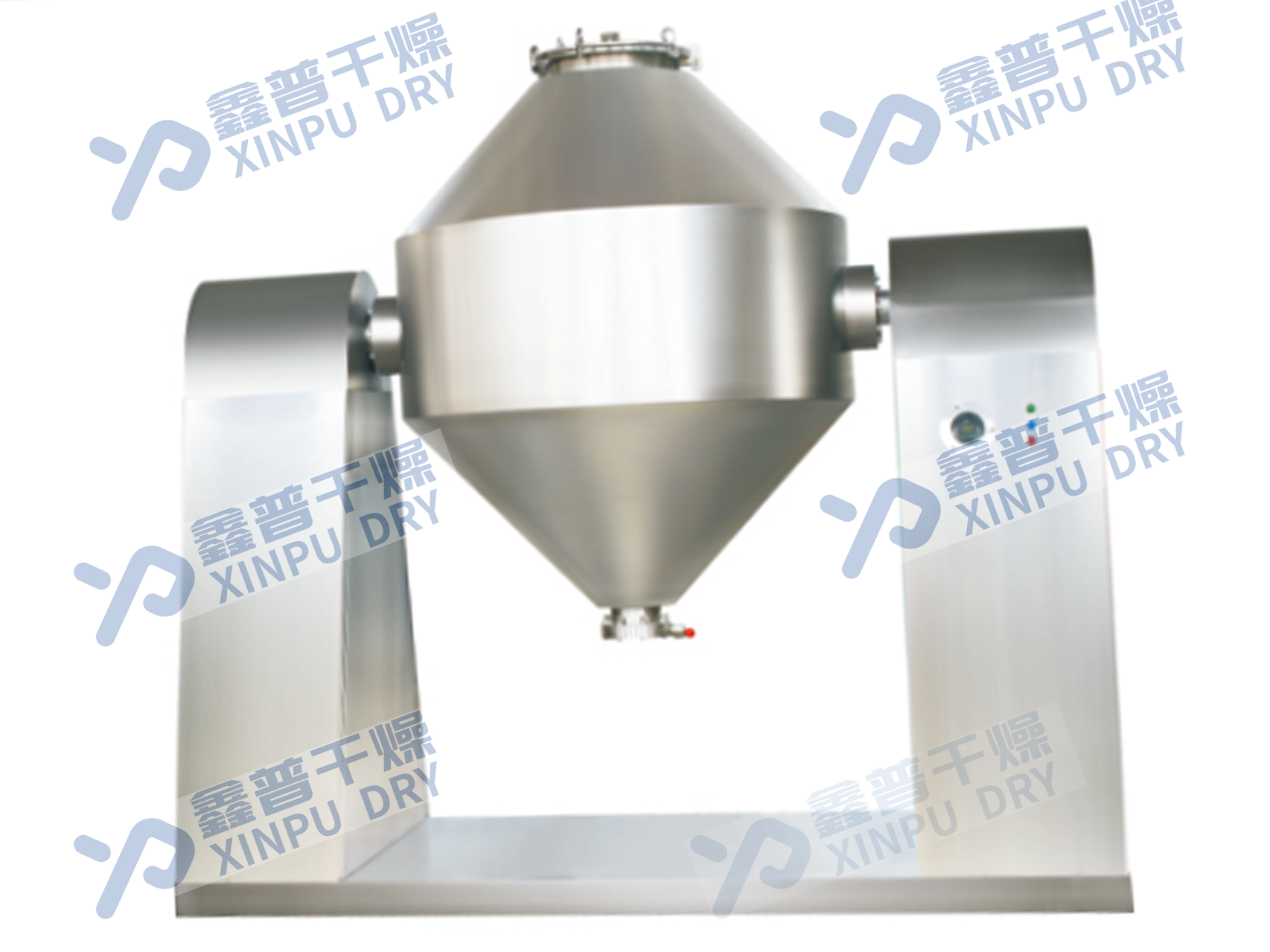

Principle of operation

Double-cone rotary vacuum dryer is a double-cone rotary tank. In the tank, steam or hot water is introduced into the jacket for heating under vacuum, and the heat contacts with wet materials through the inner wall of the tank. The water vapor evaporated after the wet material absorbs heat is pumped away by a vacuum pump through a vacuum exhaust pipe. Because the tank body is in a vacuum state, and the rotation of the tank body makes the materials turn up and down and inside and outside, the drying speed of the materials is accelerated, the drying efficiency is improved, and the purpose of uniform drying is achieved.

Heat energy (such as hot water, low pressure steam or heat transfer oil) is introduced into the closed interlayer, and the heat is transferred to the dried material through the inner shell.

Driven by power, the tank rotates slowly, and the materials in the tank are constantly mixed, thus achieving the purpose of strengthening drying.

The material is in a vacuum state, and the water (solvent) on the surface of the material is saturated and evaporated due to the decrease of vapor pressure, and it is discharged and recycled by the vacuum pump in time. The water (solvent) inside the material continuously permeates, evaporates and discharges to the surface, and the material achieves the purpose of drying in a short time.

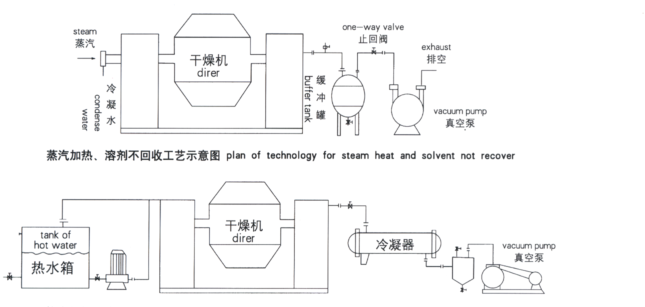

Process flow diagram

Performance characteristics

◎ When the oil is heated, it adopts automatic constant temperature control, which can dry biochemical products.

◎ And mineral raw materials, and the temperature can be between 20 and 160 DEG C..

◎ High thermal efficiency, which is more than 2 times higher than that of ordinary ovens.

◎ Indirect heating. The materials will not be polluted and meet the requirements of GMP. The equipment maintenance operation is simple and easy to clean.

◎ Recommended process placement and demonstration solvent recovery process placement.

Applied range

It is suitable for the concentration, mixing and drying of powder, granule and fiber in chemical, pharmaceutical, food and other industries, and materials that need to be dried at low temperature (such as biochemical products, etc.). It is more suitable for the drying of materials that are easily oxidized, volatile, heat-sensitive, strongly irritating and toxic, and materials that are not allowed to destroy crystals.

Technical specifications

Specification name | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

Internal volume of tank | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

Charging volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Hs (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

Rotation speed (rpm) | 4 - 6 | |||||||||

Power of motor (kw) | 0.73 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

Covers an area of length × width(mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

Swing height(mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

Design pressure in tank (MPa) | -0.1-0.15 | |||||||||

Jacket design pressure (MPa) | ≤0.3 | |||||||||

Working temperature (℃) | Within the tank ≤85 jacket ≤140 | |||||||||

When the condenser is used, the vacuum pump | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Model, power | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

When the condenser is not used, the vacuum pump | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Model, power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

Height(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |