Principle of operation

Wet material enters the spiral bed from the top feeding port, and under the action of circumferential exciting force and gravity, the material jumps from top to bottom along the spiral bed until the lowest layer is discharged; At the same time, clean hot air enters from the bottom of the spiral bed, and after fully heat and mass transfer with the materials distributed on the bed, it is discharged from the top moisture outlet. So that the wet material can be dried.

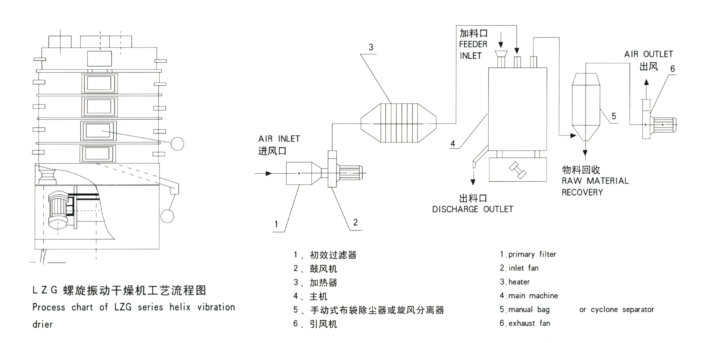

Process flow diagram

Performance characteristics

◎ Hot air passes through the material layer for many times and flows in the opposite direction to the material, so that the heat exchange is sufficient and the thermal efficiency is high.

◎ Compact structure and small floor space.

◎ The residence time of materials in the bed can be adjusted, and the operation is convenient.

◎ When the material moves in a circle from top to bottom along the spiral bed, it also jumps, thus increasing the contact between the material and the hot air and enhancing the drying effect.

◎ Continuous feeding and discharging is suitable for assembly line production, and it is easy to meet the GMP standard, which can replace the traditional box drying.

◎ There is basically no damage to the surface and shape of materials, which not only ensures the roundness of pills, but also greatly reduces the crushing rate of pills.

Applied range

The spiral vibration dryer is mainly suitable for drying traditional Chinese medicine pills, as well as granular, short strip and spherical materials in chemical, pharmaceutical, food, plastic, building materials, feed and other industries.

Technical specifications

Model | LZG-1.0 | LZG-1.2 | LZG-1.4 | LZG-1.6 | LZG-1.8 |

Diameter(mm) | 1000 | 1200 | 1400 | 1600 | 1800 |

Vibration motor power(kw) | 2×0.8 | 2×0.8 | 2×1.5 | 2×1.5 | 2×2.2 |

Outline dimension(m) | 1.2×1.2×2.7 | 1.4×1.4×2.7 | 1.6×1.6×3.3 | 1.8×1.8×3.3 | 2.0×2.0×3.3 |

Height(kg) | 1400 | 1680 | 2800 | 3100 | 3800 |

Production capacity(kg/m) | 80-120 | 120-200 | 200-280 | 280-350 | 350-450 |

Intake air temperature(℃) | 60-200 | 60-200 | 60-200 | 60-200 | 60-200 |

Air quantity(m³/h) | 1487 | 2380 | 3721 | 4462 | 5960 |

Fan power(kw) | 4.1 | 7 | 7.7 | 14 | 24 |