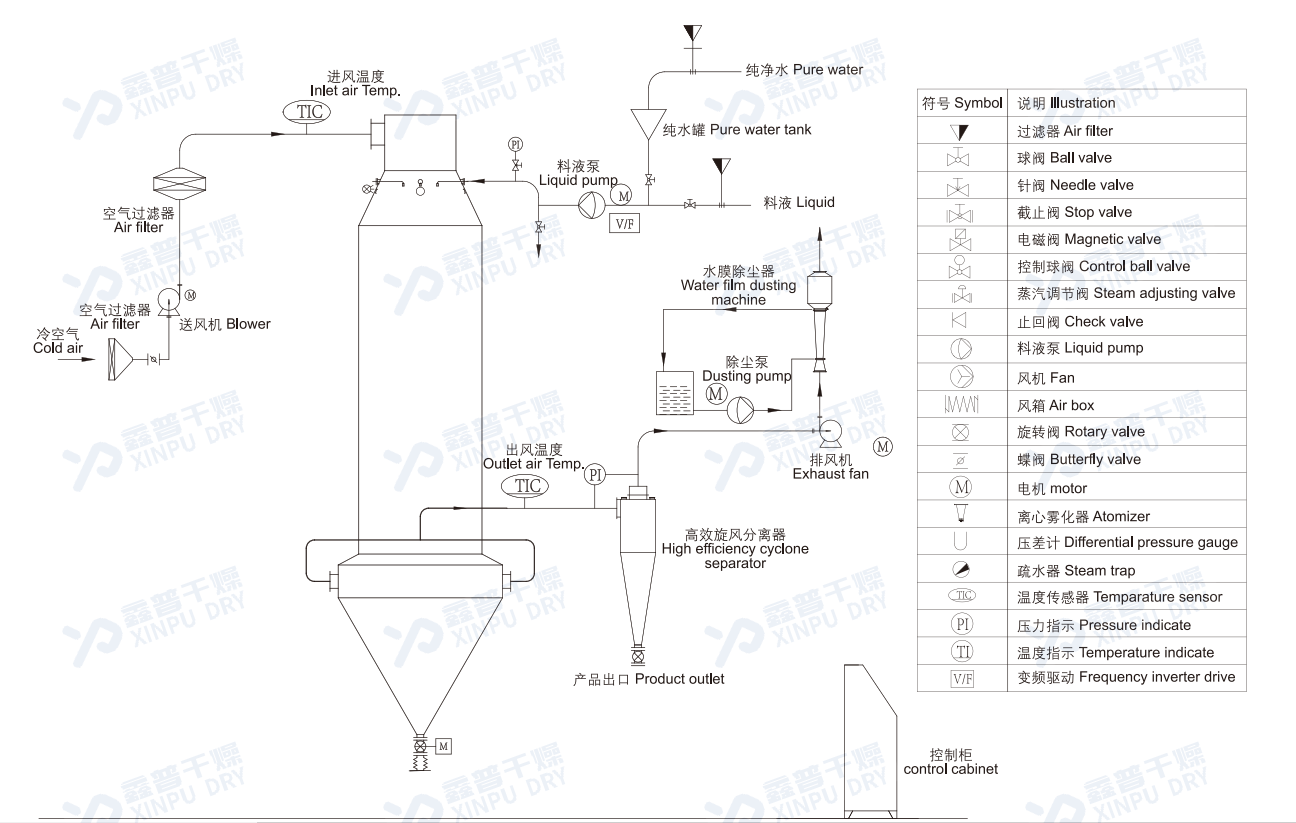

Principle of operation

The working process of this unit is that the feed liquid is input at high pressure through the diaphragm pump, and sprayed with mist droplets, and then falls down in parallel with the cold air. Most of the powder particles are collected by the discharge port at the bottom of the tower, and the waste gas and its tiny powder are separated by the cyclone separator, and the waste gas is discharged by the exhaust fan, and the powder is collected by the pollination tube at the lower end of the cyclone separator. The outlet of the fan can also be equipped with a secondary dust removal device, and the recovery rate is above 96-98%.

Process flow diagram

Performance characteristics

◎ The cooling granulation speed is fast, the surface area of the feed liquid is greatly increased after atomization, and it can be cooled and granulated instantly in the cooling air flow.

◎ All products are spherical particles with uniform particle size, good fluidity, good solubility, high product purity and good quality.

◎ It has a wide application range. According to the characteristics of materials, it can be granulated with cold air, which has strong adaptability to materials.

◎ Simple and stable operation, convenient control and easy realization of automatic operation.

Applied range

Spray cooling granulation: amino fatty acids, paraffin wax, glycerate, tallow, etc. Spray crystallization, spray concentration and spray reaction are often used.

Technical specifications

Model | Unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

Water evaporation | kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

Outline dimension(Ф×H) | mm | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×18800 | 4600×22500 |

High pressure pump pressure | mPa | 2~10 | ||||||

Power | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

Intake air temperature | ℃ | Normal atmospheric temperature | ||||||

Water content of product | % | <5(up to 0.5) | ||||||

Material recovery | % | >97 | ||||||